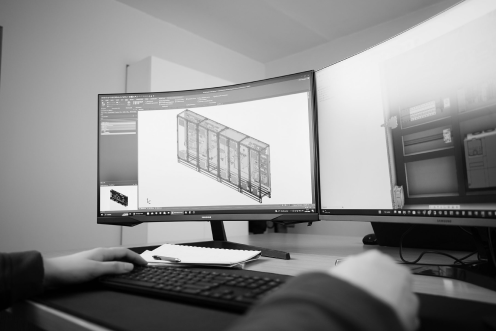

Empowering automation excellence.

We're your partner from design to maintenance,

delivering innovative solutions with a commitment

to quality and customer satisfaction.

Solution replaces monotone human work with little possibilities to improve job ergonomics with a system able to do job 24/7 with easily definable palletizing rules. Now workers can attend to more useful and interesting tasks.

Drum dryers

Conveyor dryers

Hammermills with automatic infeed of biomass based on motor load

This control algorithm allows to maximize hammermill productivity without overloading the system and causing unnecessary downtime.

Pellet presses with motors up to 400kW, with automatic infeed of biomass based on motor load.

Using this algorithm allows pellet press to reach optimal productivity.

Owners of such systems can easily retrieve data about usage and load characteristics thus planning actions for further expansion or relocation of the system. Work hour logging allows planning for maintenance to maintain downtime as little as possible in planned interwalls.

With an integrated pump load optimization algorithm system allows to balance the workload between pumps in this way achieving even distribution of wear of mechanical parts. Integrated data accumulation system allows owners to make data driven decisions(predictive maintenance, system expansion, resource relocation).

With the active sun tracking chassis of the solar panel array one can produce an additional up to 30% of energy. Our system after initial calibration is tracking the sun based on coordinates and time of the year. This way the client does not need an additional sun trajectory tracking sensor/array of sensors. If needed, the system can implement a sun tracking fine tuning algorithm based on current produced and/or sun detection sensor.

Parcel infeed system with parcel distancing.

Omnichain distribution conveyor automation.

Parcel Tracking on the conveyors for data synchronization.

Let's take a first step and start with your enquiry. Tell us about your project or goal and we will get back to you to move on with the next steps.

Please note: By submitting the contact form you agree with our Privacy Policy

Please note: By submitting the contact form you agree with our Privacy Policy

Panel building, PLC programming, Drive commissioning, HMI/SCADA configuration etc.